Mastering The Transfer Arsenal: Gold Glitter, ChromaBlast, and Large-Format DTF Gang Sheets

For modern apparel decorators, success lies in a strategic mix of core efficiency and high-impact specialty finishes. DTF Virginia provides the tools to achieve both: best-in-class general-purpose transfers combined with cutting-edge visual effects. This detailed technical and commercial analysis explores four essential products—ranging from opulent Gold Glitter and dynamic ChromaBlast to high-volume, custom DTF Gang Sheets—designed to maximize production efficiency, capture premium market segments, and deliver superior wash-durable results across all fabric types.

Gold Glitter DTF Transfers: Opulence and Durability for Premium Apparel

The Gold Glitter DTF Transfers (Product Link: Gold Glitter DTF Transfers | DTF Virginia) are a prime example of leveraging a specialty finish to capture high-margin fashion and event markets. Gold is universally associated with luxury, celebration, and premium quality. By offering this finish through the advanced DTF process, businesses can deliver the visual opulence of gold glitter with commercial-grade durability that traditional methods often fail to achieve.

Technical Superiority of DTF Glitter Over Vinyl

Traditional methods for applying glitter (such as Heat Transfer Vinyl - HTV or screen printing) often suffer from two major flaws: shedding and a heavy, stiff hand feel. Gold Glitter DTF solves both. The micro-glitter particles are encapsulated within the flexible polymer adhesive layer, ensuring virtually zero shedding during washing or wear. Furthermore, the transfer is thinner and softer than a layer of cut glitter vinyl, providing a much better drape and flexibility on the garment. This combination of high-end visual appeal and superior comfort makes Gold Glitter DTF ideal for luxury brands, cheerleading uniforms, bachelorette parties, and holiday merchandise.

Market Positioning for High-Value, Event-Based Sales

The addition of a reliable, non-shedding Gold Glitter option allows a business to pivot towards high-value, event-based sales. Clients planning weddings, milestone birthdays, high-end corporate events, or holiday collections are often budget-flexible but quality-demanding. Gold Glitter transfers immediately command a premium price point over standard colors. The quality guarantee—that the gold will remain brilliant and intact for the life of the garment—secures repeat business from clients who prioritize aesthetics and longevity. This specialty product acts as a profit margin accelerator by tapping into demand for celebratory, luxury apparel.

Best Practices for Gold Glitter Application

To ensure the best result, the Gold Glitter transfer requires precise heat, pressure, and peel timing. A two-step press method is often recommended: an initial press to set the transfer and a short second press (using parchment paper) after the cool peel to solidify the adhesive and maximize the soft hand feel. The opacity of the Gold Glitter DTF means it pops brilliantly on both light and dark fabrics, providing true versatility across your entire stock of cotton, polyester, and blended garments.

| Gold Glitter DTF Feature | Technical Advantage | Commercial Benefit |

| Finish Quality | Encapsulated Micro-Glitter | Zero shedding and high opulence for premium look. |

| Hand Feel | Soft, Flexible Polymer Layer | Superior comfort compared to stiff glitter vinyls. |

| Market Segment | Luxury, Events, Celebrations | Justifies premium pricing and high-margin sales. |

| Adhesion | Strong DTF Adhesive Base | Excellent wash durability, securing customer satisfaction. |

ChromaBlast DTF Transfers: The Ultimate for Cotton Color Reproduction

ChromaBlast DTF Transfers (Product Link: ChromaBlast DTF Transfers are a specialized product designed to leverage the unique color depth and ink science of the ChromaBlast system within the convenience and durability of the DTF process. While traditional DTF excels in universal compatibility, ChromaBlast is engineered to deliver an unmatched color gamut and exceptional detail resolution specifically on cotton and cotton-blend fabrics.

Ink Science and Color Fidelity on Cellulose Fibers

ChromaBlast technology, typically associated with dye-sublimation on cotton, utilizes specialized chemical processes that result in a high level of color saturation and adherence to cellulose fibers. When integrated into the DTF transfer process, these specialized inks deliver colors that are often more vivid and detailed than standard DTF CMYK, particularly in complex photographic and finely detailed artwork. This fusion provides the best of both worlds: the incredible vibrancy and detail resolution of the ChromaBlast system combined with the superior wash durability and high-opacity white backing of DTF.

Strategic Use for Branding and Photographic Artwork

The ChromaBlast DTF offers a significant competitive advantage for businesses that service clients requiring photographic realism and razor-sharp logo details on cotton apparel (e.g., promotional wear, custom t-shirts, high-detail merch). It allows print shops to confidently handle challenging color gradients and small, intricate details that might blur or fade using conventional methods. For clients whose brand identity relies heavily on photographic elements or highly complex logos, ChromaBlast DTF becomes the premium-tier offering, justifying a higher service charge due to its superior final aesthetic.

Simplicity of Application and Fabric Focus

ChromaBlast DTF maintains the straightforward weed-free, single-step heat press process common to all DTF transfers. This simplicity ensures fast fulfillment and minimal labor costs. By focusing its superior color science on cotton and cotton-blend fabrics, it eliminates the need for any complex fabric pre-treatment, saving time and simplifying inventory management. This makes it a high-efficiency choice for common apparel items where color pop is paramount.

| ChromaBlast DTF Feature | Technical Advantage | Commercial Benefit |

| Ink System | Specialized ChromaBlast Chemistry | Unmatched color vibrancy and detail resolution on cotton fibers. |

| Compatibility | Optimized for Cotton and Cotton Blends | Superior aesthetic quality on the most common apparel fabrics. |

| Artwork Quality | High Detail and Photographic Realism | Ideal for high-end corporate or merchandise clients with complex artwork. |

| Durability | DTF Adhesive/White Backing | Excellent wash fastness and opacity on all fabric colors. |

22" Wide Custom DTF Gang Sheet: Scaling Production and Maximizing Throughput

The 22" Wide Custom DTF Gang Sheet (Product Link: 22in Wide Custom DTF Gang Sheet) is the core productivity engine for any high-volume apparel operation. This wide-format sheet is all about economies of scale, maximizing media usage, and achieving the lowest possible cost-per-transfer (CPT) for standard, high-quality DTF production.

Efficiency and Economics of Wide-Format Gang Sheeting

DTF gang sheets are crucial for maximizing substrate utilization. By providing a full 22-inch width, businesses can strategically arrange diverse transfer designs (front logos, back designs, sleeve prints, hat logos) onto a single continuous sheet. This process eliminates white space and reduces film waste, directly translating to a lower overall CPT. For large orders or regular fulfillment, running the widest possible gang sheet dramatically cuts both material cost and production time (as fewer presses are needed per garment set), ensuring maximum throughput and superior cost control for the business.

Versatility and Dependability for High-Volume Orders

The 22" DTF Gang Sheet delivers the core benefits of DTF: vibrant CMYK color, high-opacity white base, and universal fabric compatibility. This dependability makes it the go-to solution for high-volume, general-purpose orders, such as corporate uniforms, school spirit wear, and large merchandise runs. Knowing that the transfer will adhere flawlessly and remain durable on almost any fabric type simplifies inventory and significantly reduces the risk of production errors, which is critical when handling hundreds or thousands of units.

Streamlined Workflow and Fulfillment Speed

By receiving the transfers pre-printed on a single roll, the fulfillment process becomes highly efficient. The press operator simply cuts the required transfers and presses them directly onto the garment. This weed-free, single-press application is vastly faster than cutting and weeding vinyl or managing multiple pieces of sublimation paper, enabling the business to handle significantly higher order volumes with the same amount of labor. This speed is a key differentiator in the competitive contract printing market.

| 22" Wide DTF Gang Sheet Feature | Technical Advantage | Commercial Benefit |

| Sheet Width | Full 22 inches Wide | Maximizes film utilization; achieves lowest cost-per-transfer (CPT). |

| Function | Core High-Volume Production | Ideal for large runs (corporate, school, events) and maximizing throughput. |

| Process | Weed-Free, Single-Step Press | Drastically reduces labor time and simplifies fulfillment workflow. |

| Durability | Universal DTF Quality | Flawless adhesion and durability on all common fabric types. |

Custom DTF Gang Sheet Builder: Empowering Design and Order Control

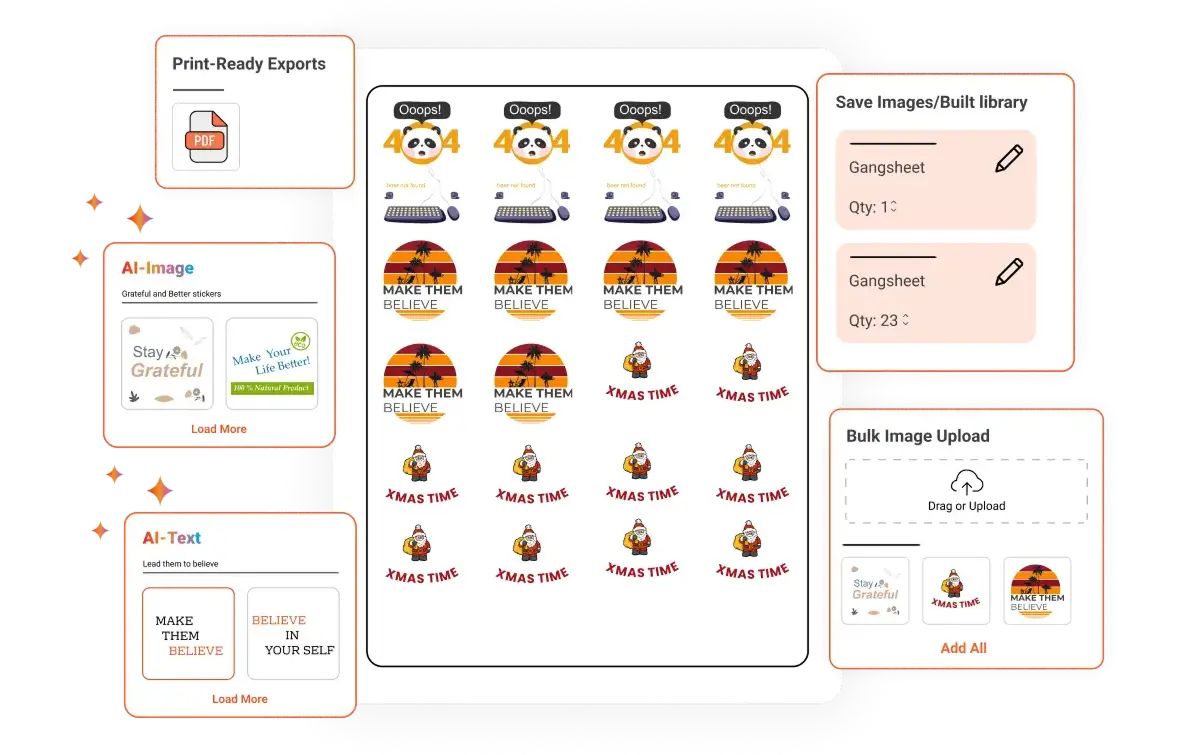

The Custom DTF Gang Sheet Builder (Product Link: Custom DTF Gang Sheet Builder | DTF Virginia) is a dedicated software solution designed to empower the customer with precise control over their final print output, ensuring seamless integration between design and production. This tool is essential for businesses that rely on fast, custom layout configurations for diverse, multi-design orders.

Software-Driven Workflow and Layout Optimization

The Gang Sheet Builder is a user-friendly interface that allows the customer to upload multiple design files and precisely arrange them within the sheet's dimensions. This is a crucial feature for maximizing density and reducing cost. The builder allows the user to rotate, scale, and adjust the spacing between elements to eliminate wasted film space. By putting this optimization control in the hands of the designer, the business ensures that the customer gets the maximum possible value out of every linear foot of film purchased, leading to better order profitability and reduced back-and-forth communication.

Accuracy and Reduced Error Rates

A critical benefit of the builder is reduced error rates. By visually confirming the exact placement and scaling before submission, the risk of print errors due to miscommunication or file issues is drastically lowered. The builder functions as a precise digital proof, guaranteeing that the final printed sheet matches the customer's vision for their garment placements. This increased accuracy saves the business time, material, and the cost of reprinting incorrect orders, contributing significantly to a healthy bottom line.

Versatility for Diverse Custom Orders

The builder is perfect for high-mix, low-volume (HMLV) orders—a common segment for custom apparel shops. Whether the customer is combining a dozen different team numbers, small pocket logos, and one large back graphic, the builder handles the complexity. This versatility allows the business to confidently accept intricate, multi-design orders that would be cumbersome with older printing methods, broadening the business's scope and client base.

| Gang Sheet Builder Feature | Technical Advantage | Commercial Benefit |

| User Interface | Drag-and-Drop Layout Control | Empowers customer to maximize film density and lower CPT. |

| Proofing | Accurate Visual Confirmation | Significantly reduces print errors, waste, and customer dissatisfaction. |

| Workflow | Seamless File-to-Print Submission | Accelerates the ordering and pre-press process for fast fulfillment. |

| Order Type | High-Mix, Low-Volume Support | Allows efficient acceptance of complex, multi-design custom orders. |

Final Summary: The Integrated Transfer Strategy

A winning apparel strategy is built on the right transfers for the right job. Use the Custom DTF Gang Sheets for core efficiency and volume. Employ Gold Glitter for high-margin luxury appeal and non-shedding quality. Leverage ChromaBlast DTF when cotton demands superior color fidelity and detail. Finally, utilize the Gang Sheet Builder and 22" Wide Sheets to optimize every inch of film and maximize your production throughput. DTF Virginia provides the tools to manage complexity, scale volume, and dominate specialty markets simultaneously.

Transform your production efficiency and specialty offerings. Click the links below to secure these essential transfers from DTF Virginia:

For Non-Shedding Luxury: Order your high-impact Gold Glitter DTF Transfers.

For Superior Color on Cotton: Achieve unmatched detail with ChromaBlast DTF Transfers.

For Max Production Volume: Scale your business with the 22in Wide Custom DTF Gang Sheet.

For Precision Layout Control: Design perfectly optimized sheets using the Custom DTF Gang Sheet Builder.